Manufacturing and assembly

Manufacturing and assembly

Our manufacturing focuses on custom air pollution prevention equipment as defined by our engineering teams detailed drawings and specification to meet each costumer specific requirements with the highest standard. Our Quality control supervisors provide personal escort for each manufacturing project on a daily basis. In addition, manufacturing in house allows us to intervene professionally and quickly […]

Cost effective solution Retrofitting R.T.O.

RTO systems are industry standards for treating and destroying organic and odorous pollutants and are defined as Best Available Technology (BAT) for treating VOC. A factory producing food products received a demand from the Ministry of Environmental protection to begin testing for organic pollutants in chimneys that had no expectancies of having any presence […]

Novel odor prevention filters.

Active Carbon Filtration systems – Odor Treatment – MRF materials recovery facility Active carbon-based systems are the industry standard for treating organic and odorous pollutants in the air. Active carbon is an inert solid which is also adsorbent, available, and cheap. These qualities make it an ideal for the removal of organic and odorous pollutants […]

Active carbon, When is it the best option?

Active carbon-based systems are the industry standard for treating organic and odorous pollutants in the air. Active carbon is a solid which is inert, absorbent, available, and cheap. These qualities make it an ideal remover of organic and odorous pollutants in water and gas currents. Active carbon treats pollutants in an adsorption process, where interactions […]

How do absorption systems and regenerative thermal oxidizers interact?

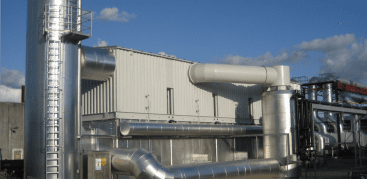

Regenerative thermal oxidizers are an industry standard for treating and destroying organic and odorous pollutants. Oxidation of organic materials is a process where organically polluted air is filtered through a system with a high-temperature combustion cell. The high temperature in the cell incites a combustion reaction between the organic pollutant with the oxygen in the […]

Pilot system for selecting the most cost – effective solution

Oxidation of organic materials is a process where organically polluted air is filtered through a system with a high-temperature combustion cell. The high temperature in the cell incites a reaction between the organic pollutant with the oxygen in the air called Combustion. The products of the said reaction are CO2 (Carbon Dioxide) and water considered […]

Acid vapor and halogen treatment system from VOC combustion process in the pharma industry

ABP Chemical Engineering and Ventilation Engineering Ltd. specializes in the design and installation of systems for the treatment of emissions of acid fumes and halogen vapor. Our company has designed and installed numerous systems that meet the most strict environmental standards. A large Pharmaceutical manufacturing company has received a request from the Ministry of the […]

RTO system for the treatment of VOC emissions from solvents in the Food Industry – Retrofitted system.

ABP Chemical Engineering and Ventilation Ltd. specializes in the design and installation of RTO treatment systems for VOC emissions treatment In the food industry. A large food manufacturing plant has received a request from the Ministry of the Environmental protection prevent and treat VOC emissions from production processes. The budget for a project that […]